Table of Contents

Picture this: You’re managing a billion-dollar power plant project. The contractor claims they’re entitled to extra payment because of design changes. Your client says the delays are the contractor’s fault. And somewhere in a 300-page contract, the answer exists.

But can you find it? This happens more often than you’d think. EPC projects fail not because of poor engineering. They fail because of poor contract management. In EPC and construction projects, contracts are everything. They define who does what. Who pays for what? Who takes the blame when things go wrong? And in projects where a single delay can cost millions, getting contracts wrong isn’t an option.

That’s why specialized training in contract management has become critical. This isn’t just about reading legal documents. It’s about understanding risk. Managing change. Handling disputes before they explode. And keeping massive projects on track.

Let’s break down what you need to know.

Why EPC & Construction Contract Management Needs Specialized Training

EPC stands for Engineering, Procurement, and Construction. These projects are different beasts altogether. Unlike regular construction jobs, EPC contracts bundle everything together. The contractor designs the facility. They buy all the equipment. They built it. And then they guarantee it works as promised.

That’s a lot of risk in one package. Most EPC projects use standard contract forms. FIDIC’s Silver Book is the most popular. These documents run hundreds of pages. They allocate risks between parties in very specific ways. They set out detailed procedures for everything from variations to disputes. Miss a critical clause? You could lose millions.

Here’s what makes EPC contracts so complex:

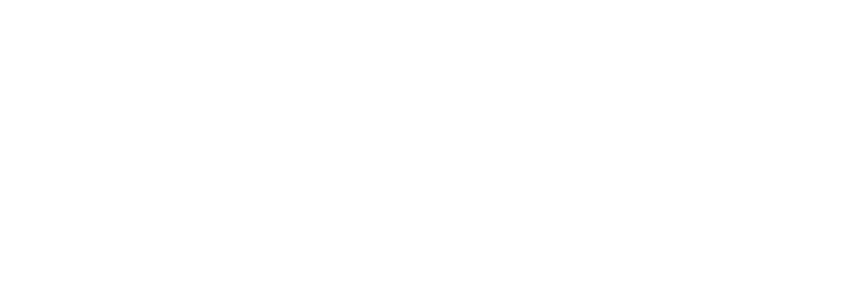

Multiple stakeholders with conflicting interests: You’ve got the client who wants quality at low cost. The main contractor manages risk and profit. Dozens of subcontractors are doing actual work. Suppliers providing equipment. Banks are financing the project. Government regulators are watching compliance.

Each party wants to shift risk away from itself.

Massive scope and scale: EPC projects often involve entire facilities. Power plants. Refineries. Highways. Metro systems. We’re talking years of work and billions in investment.

One ambiguous clause can trigger disputes that last longer than the construction itself.

Design obligations create unique risks: In traditional construction, the client provides the design. The contractor just builds it. In EPC, the contractor designs and builds. If the design doesn’t work, that’s on them.

This flips traditional risk allocation on its head.

Constant changes and variations: No matter how good the planning, things change. The client wants modifications. Site conditions differ from assumptions. Regulations change mid-project. Equipment suppliers can’t deliver on time.

Each change needs proper documentation. Proper approval. Proper cost and time impact assessment. Without training, these variations become nightmares.

Performance guarantees add pressure: EPC contractors often guarantee that the facility will perform to certain standards. Power output. Production capacity. Efficiency levels.

Fail to meet these guarantees? You’re paying penalties.

Regulatory and compliance complexity: Construction projects face environmental laws. Safety regulations. Quality standards. Local content requirements. Labor laws.

Contracts must address all of these. And someone needs to track compliance throughout the project. I’ve seen projects where engineers were brilliant. The construction was top-notch. But poor contract management led to disputes that ate up all the profit. Sometimes, more than the profit. Training prevents this. It gives professionals the tools to navigate these complexities. To spot risks early. To document everything properly. To handle changes without chaos. To prevent small issues from becoming legal battles.

What a Good EPC / Construction Contract Management Training Course Should Cover

A comprehensive training program needs to cover the full spectrum of contract management. Not just theory. Real, practical skills you can use on Monday morning.

Here’s what should be included:

Understanding EPC & FIDIC Contracts

Start with the basics. What makes EPC delivery different from design-bid-build or construction management approaches? In EPC, one entity takes responsibility for everything. This changes risk allocation fundamentally. Then dive into FIDIC contracts. These standard forms dominate international construction. The Red Book for construction. The Yellow Book for design-build. The Silver Book for EPC turnkey.

Each book has different risk profiles. The Silver Book, for instance, gives the contractor full design risk but also more control. The employer gets a fixed price and guaranteed performance. But here’s the thing. Many people think FIDIC contracts are just templates you fill in. Wrong.

FIDIC provides General Conditions that are standard. But the Particular Conditions are where you customize everything. Payment terms. Delay liquidated damages. Performance guarantees. Dispute resolution procedures.

Understanding the hierarchy of contract documents is critical. What happens when the drawings contradict the specifications? When do the Particular Conditions conflict with the General Conditions?

The contract tells you. But you need to know where to look.

| Aspect | EPC | Design-Bid-Build |

|---|---|---|

| Risk Allocation | Contractor-heavy; contractor takes design and performance risk | Shared; client provides design while contractor executes construction |

| Design Responsibility | Contractor handles full design and build responsibility | Client or consultant provides detailed design |

| Price Model | Fixed lump-sum or turnkey model | Unit-rate or measurement-based pricing |

| Change Management | Strict variation rules; changes can be costly | Variations are common and handled through change orders |

| Performance Guarantees | High performance guarantees (output, efficiency, etc.) | Limited to workmanship quality |

| Suitable Projects | Large, complex, turnkey plants requiring single-point responsibility | Projects where clients want design control or phased execution |

Contract Drafting and Negotiation

This is where rubber meets road. Drafting isn’t about legal language. It’s about clarity. About anticipating problems. About making sure everyone understands their obligations the same way. The scope of work section causes more disputes than any other part. Why? Because a vague scope means arguments about what’s included and what’s extra. Good training teaches you to write a scope that’s specific but not limiting. To use clear milestones. To define deliverables precisely. To address the interfaces between different packages of work.

Negotiation is different. It’s about finding balance. The contractor wants to limit liability. The client wants maximum protection. Somewhere in the middle is a deal both can live with. Training should cover negotiation strategies. How to identify your walk-away points. How to trade provisions. When to push hard and when to compromise. I once watched a negotiation where the client insisted on unlimited liability. The contractor walked away. Three months later, the client came back accepting reasonable caps. They’d learned the hard way that unreasonable demands just increase prices or lose bidders.

Contract Lifecycle Management in Construction

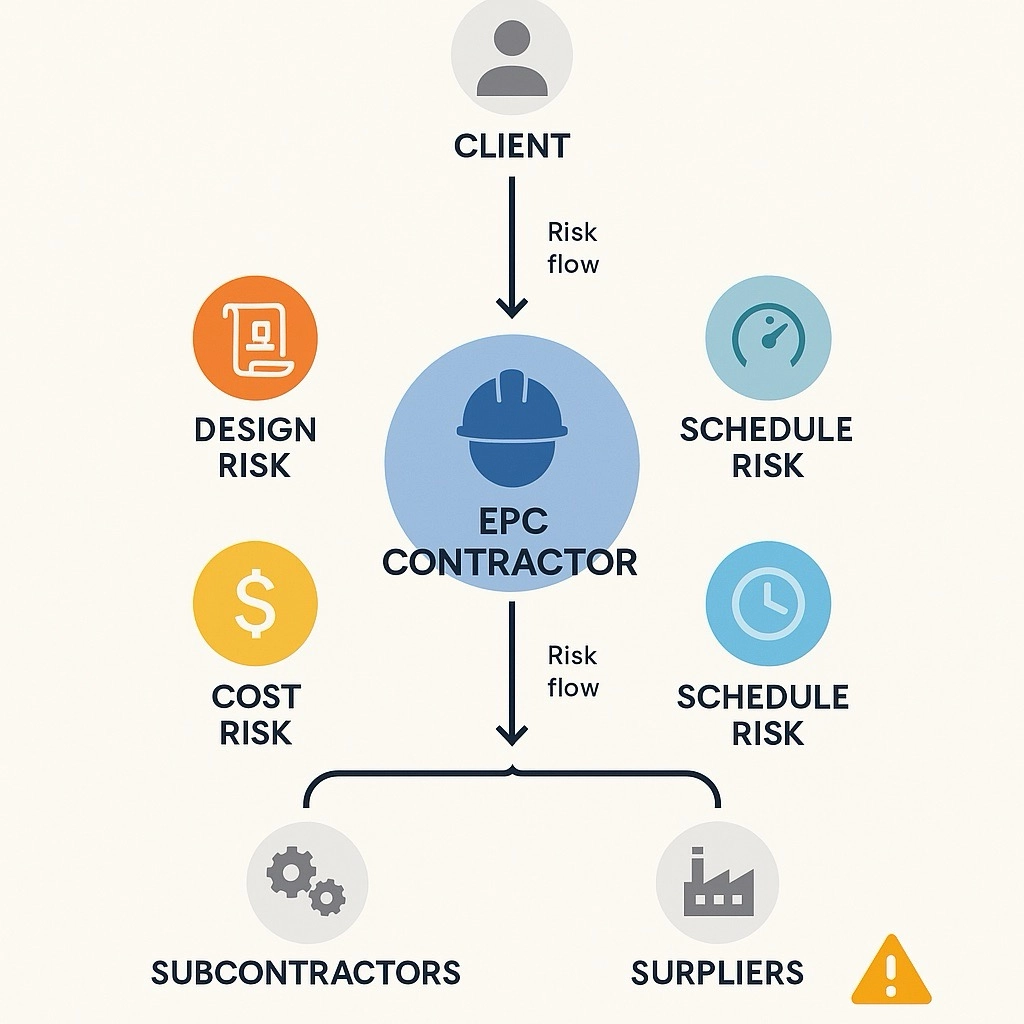

Contracts aren’t static documents you sign and forget. They’re living things that need management throughout their life. The lifecycle starts with creation. Someone drafts the contract based on project needs. Then comes negotiation and revision. Multiple rounds often. Then approval by authorized parties. Signing and execution.

But that’s just the beginning. During performance, you need to monitor obligations. Track deliverables. Process payments. Handle variations. Manage compliance. Document everything.

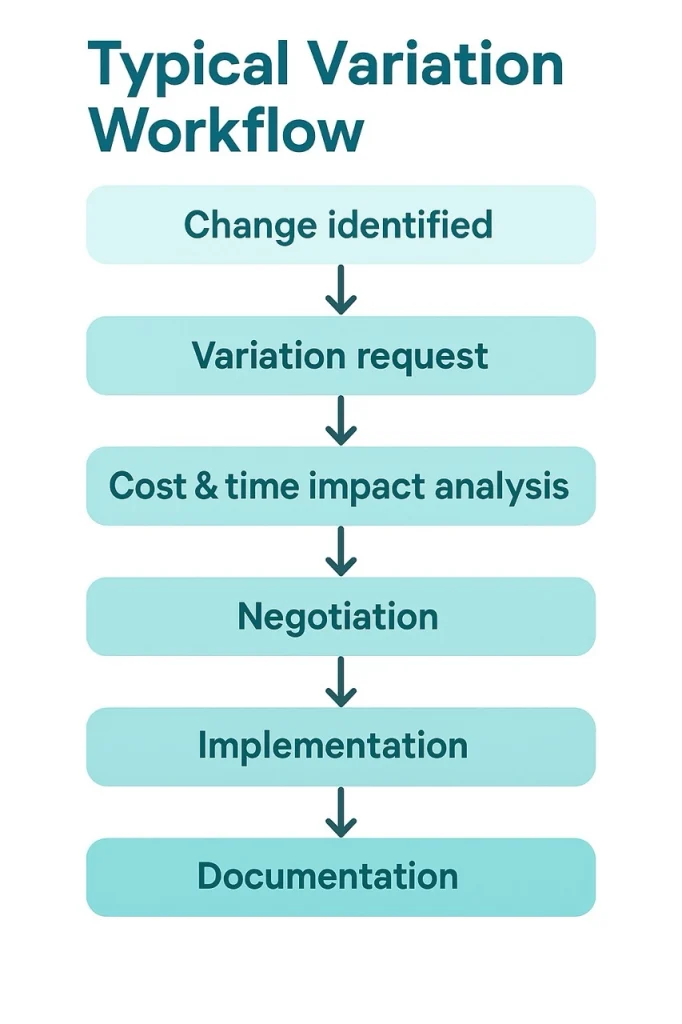

Change management is huge. Most contracts will see dozens or hundreds of changes. Each needs a proper procedure. Request for variation. Cost and time impact assessment. Approval. Implementation. Documentation.

Skip steps? You’ll face disputes about whether the change was authorized. Whether payment is due. Whether the delays were justified. Then comes completion and close-out. Final accounts. Defect liability. Performance testing. Final payments. Dispute resolution, if needed.

Good contract lifecycle management means nothing falls through the cracks. Every deadline is tracked. Every obligation is monitored. Every change is documented. Modern CLM software helps. It alerts you to approaching deadlines. Stores all versions of documents. Tracks approvals. Maintains audit trails.

But software is just a tool. You need to understand the principles first.

Risk Allocation & Management

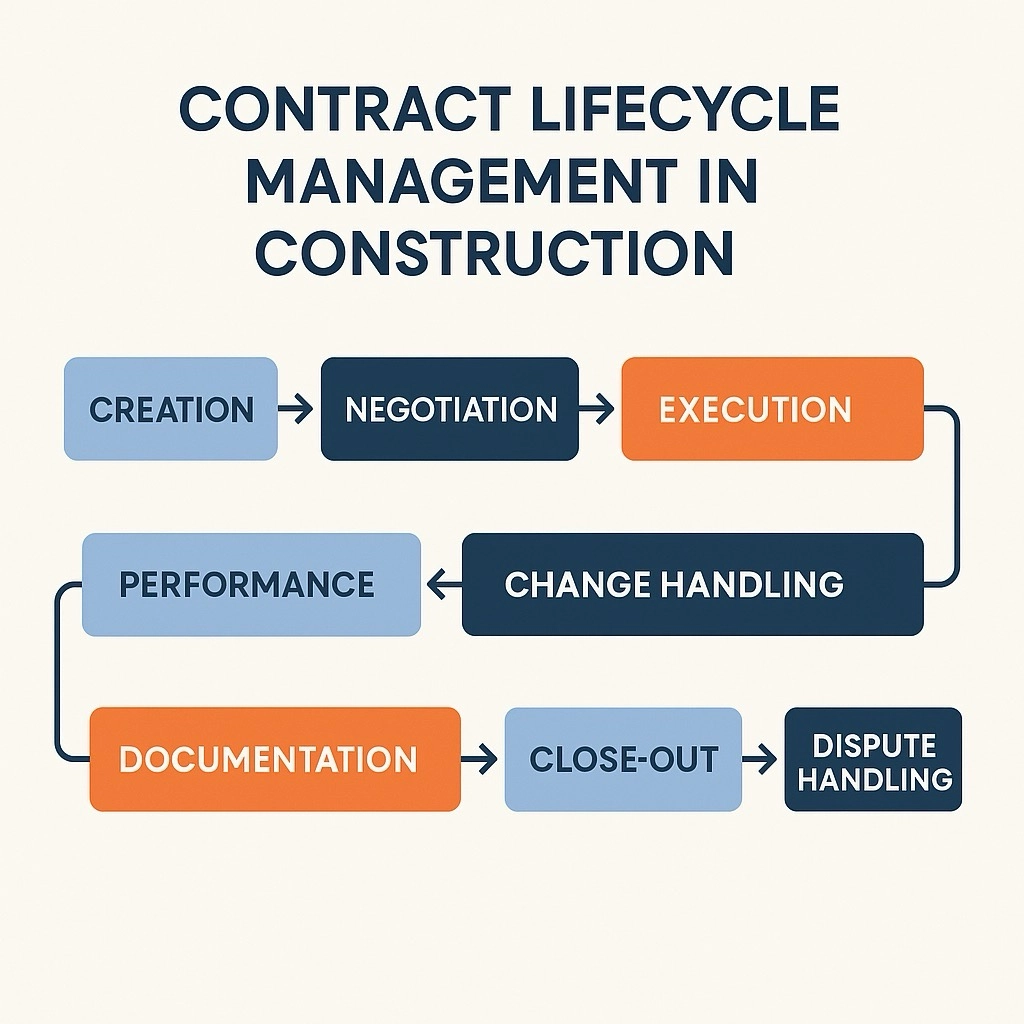

This is the heart of EPC contracts. Every project has risks. Design risks. Construction risks. Weather risks. Regulatory risks. Financial risks. Political risks. Force majeure events.

The question isn’t whether risks exist. It’s who bears them. In EPC contracts, the contractor typically takes more risk than in traditional contracts. They take design risk. They often take price risk through lump-sum pricing. They take performance risk through guarantees. But not all risks. The client usually keeps site condition risks if they provide the geotechnical data. They keep risks related to their own approvals and decisions. They keep certain political and regulatory risks. Training needs to cover how to identify risks. How to assess their likelihood and impact. How to allocate them fairly. How to mitigate them through insurance, bonds, and guarantees.

I’ve seen contracts where risk allocation was so one-sided that contractors added huge contingencies. The client thought they were protected. But they just paid more up front. Fair risk allocation means putting risks with the party best able to control them. At the lowest cost.

Change Orders, Variations & Claims Handling

If there’s one area that causes the most disputes, it’s this.

Changes are inevitable. The client changes their mind about the design. Site conditions differ from expectations. Regulations change. Equipment takes longer to deliver. Each change should follow a formal process. The requesting party issues a variation order or change request. The contractor assesses the impact on cost and time. They submit a proposal. The client reviews and negotiates. Both agree. The change is implemented.

Sounds simple. Rarely is. Problems happen when changes are ordered verbally. Or work proceeds before agreement on cost. Or the contractor claims every small issue is a compensable change. Or the client disputes whether something really is a change.

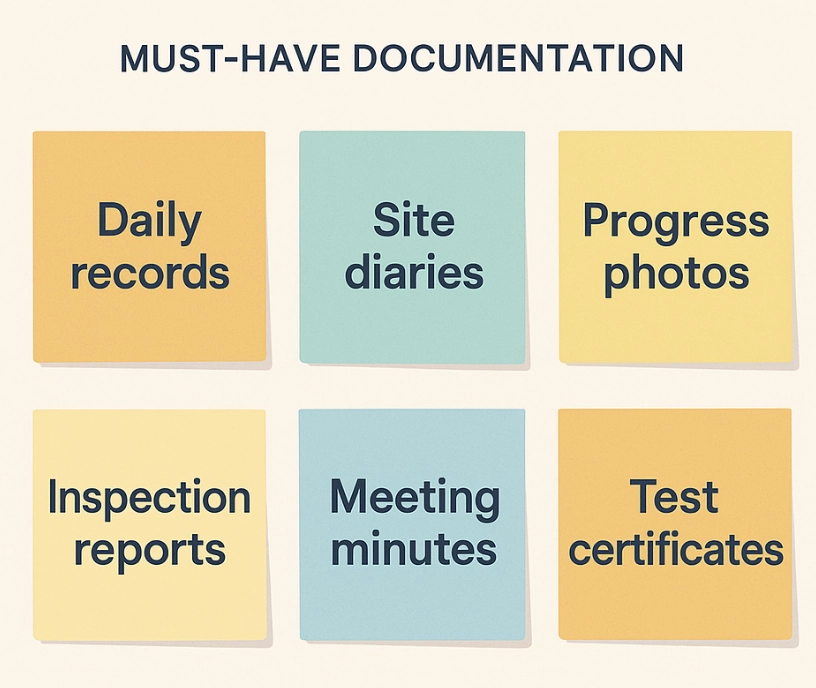

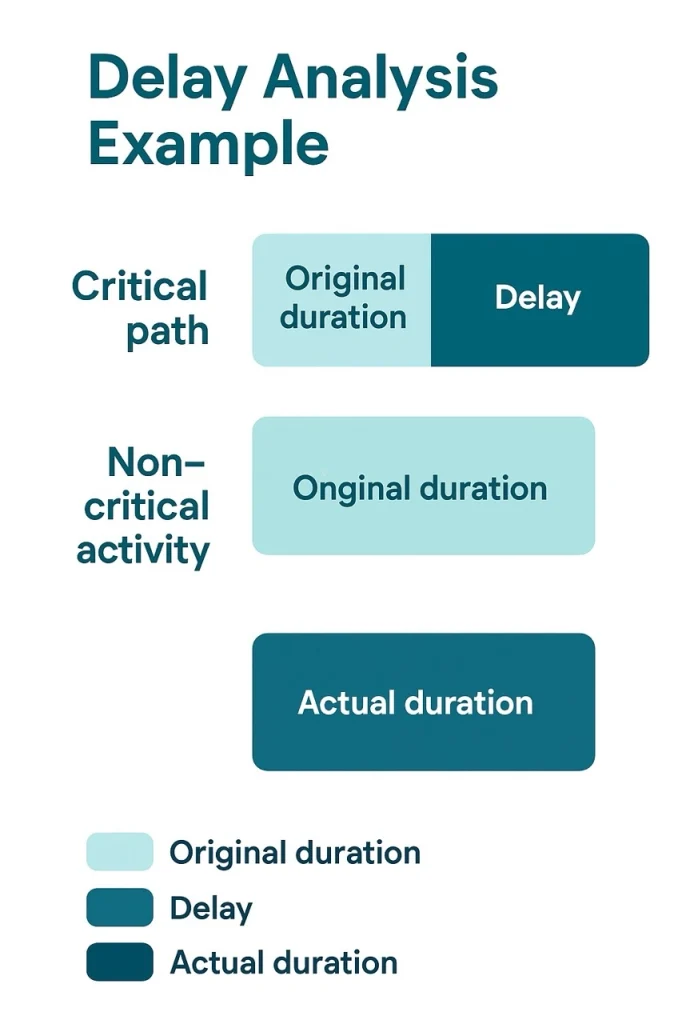

Good documentation is everything. Daily site records. Meeting minutes. Correspondence. Progress photos. Everything that shows what was agreed and what actually happened. Extension of Time claims are particularly tricky. The contractor must prove that delays were caused by events beyond their control. That they’re entitled to relief under the contract. That they took reasonable steps to mitigate the delay.

The client often argues that delays were the contractor’s fault. Or were concurrent with contractor delays. Or weren’t properly notified. Training teaches you the procedures. The notice requirements. The documentation is needed. How to prepare and defend claims. How to analyze delay using the critical path method. Because when millions are at stake, gut feel doesn’t cut it.

Subcontract Management & Coordination

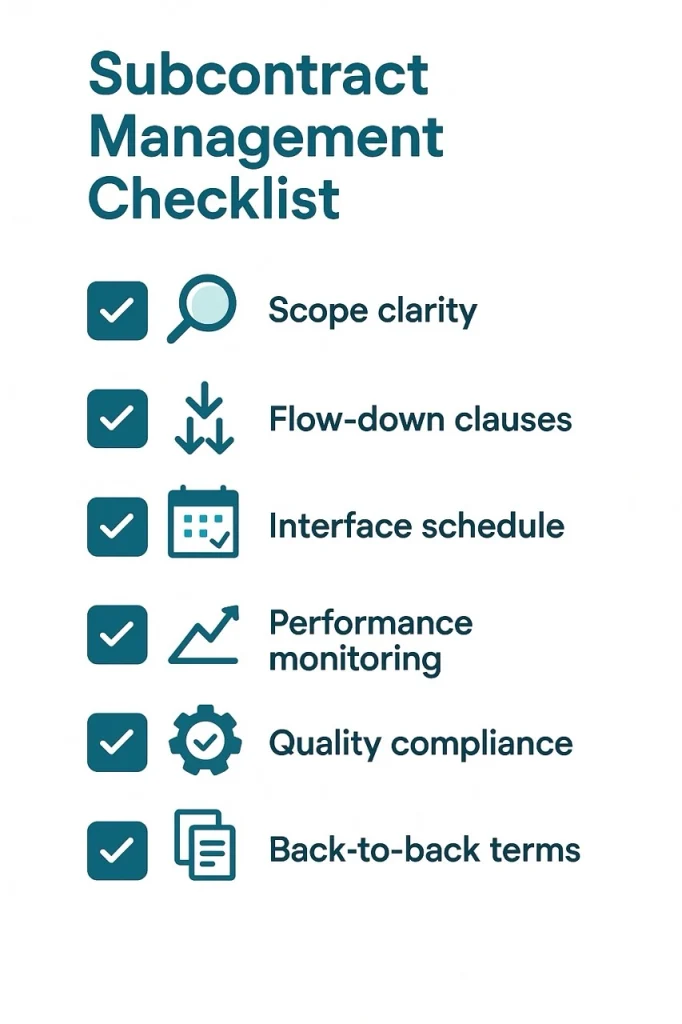

Main contractors rarely do all the work themselves. They subcontract most of it. This creates additional complexity. The main contract flows down to subcontracts. But subcontract terms might not exactly match. Obligations and interfaces need careful management. What happens when the subcontractor delays? The main contractor is still liable to the client. They need to manage subcontractor performance aggressively while maintaining the subcontractor relationship.

What happens when the main contract gets varied? The variation might affect subcontract work. Does the subcontractor get a matching variation? Or must the main contractor absorb the difference? Subcontract drafting requires skill. The scope must be clear. Payment terms must incentivize performance. The subcontractor must have adequate insurance and bonds. Quality and safety standards must be enforceable.

Interface management is critical. Where one subcontractor’s work meets another’s, who does what? Who coordinates? Who fixes problems? I’ve seen projects where poor subcontract management multiplied problems. The main contractor couldn’t control subs. Quality suffered. Delays cascaded. Costs exploded. Training covers best practices. How to select subcontractors. How to draft subcontracts. How to monitor performance. How to coordinate between subs. How to handle subcontractor claims.

Contract Administration & Compliance

The daily grind of contract management. Not glamorous but essential. Someone needs to track milestones. Monitor progress against the schedule. Review contractor submittals. Process payment applications. Verify compliance with specifications. Conduct inspections and tests.

Documentation is king. Progress reports. Site diaries. Photographs. Test certificates. As-built drawings. Meeting minutes. This documentation serves multiple purposes. It tracks whether parties are meeting obligations. It provides evidence if disputes arise. It maintains institutional memory as people rotate off projects.

Compliance monitoring is critical. Is the contractor meeting safety requirements? Environmental standards? Quality specifications? Labor law obligations? Failure to monitor and enforce compliance early means problems compound. By the time you notice, fixing them is expensive or impossible.

Good training emphasizes systems. Checklists. Schedules. Reporting templates. Review procedures. Approval workflows. Because administration might seem boring. But it’s the foundation everything else rests on.

Dispute Resolution & Claims Management

Despite best efforts, disputes happen. The contract should specify dispute resolution procedures. Many FIDIC contracts use a tiered approach. First, the Engineer or Employer’s Representative decides. If a party disagrees, they can escalate to a Dispute Adjudication Board. If still unresolved, arbitration.

Understanding these procedures is vital. Missing a deadline for notice can waive your right to claim. Following the wrong procedures can invalidate your claim. Dispute resolution boards are particularly important in EPC projects. These are independent experts appointed at project start. They visit the site regularly. They understand the project. When disputes arise, they can resolve them quickly.

This beats waiting years for arbitration. By which time the project is finished, and the evidence is cold. Claims management requires specific skills. How to prepare a comprehensive claim. How to prove causation and quantum. How to present evidence effectively. How to respond to the other party’s claims.

Training should include case studies. Review actual disputes. Analyze what went wrong. What the parties argued. How the tribunal decided. What lessons emerge? Because learning from others’ mistakes is cheaper than making your own.

Practical Case Studies & Real-World Scenarios

Theory only goes so far. You need practice. Good training includes case studies from real projects. Changed names for confidentiality. But real situations.

A power plant where the contractor claimed rock conditions were different from those specified. The client disputed. What does the contract say? What evidence exists? How should this be resolved? A highway project where the contractor says the client’s design was deficient. Rework costs millions. Are they entitled to compensation?

Workshop exercises are valuable. Mock contract drafting. Negotiation role plays. Variation order processing. Claims preparation. These exercises reveal gaps in understanding. They build confidence. They let you make mistakes in a safe environment.

I remember a training where we role-played a negotiation. Half the participants played contractors. Half played clients. Each side thought its position was completely reasonable. Only when they switched roles did they understand the other perspective. That’s the kind of insight you can’t get from reading.

Use of Tools & Technology in Contract Management

Modern contract management increasingly relies on technology. Contract Lifecycle Management software stores all contract documents. Tracks obligations and deadlines. Sends alerts and reminders. Manages approval workflows. Maintains version control and audit trails.

Some systems include clause libraries. Pre-approved language for common provisions. This ensures consistency and reduces drafting time. Digital collaboration platforms enable teams to review and comment on contracts. Track changes. Maintain a single source of truth. E-signature tools speed up execution. No more printing, signing, scanning, or emailing. Sign electronically with full legal validity.

Document management systems organize the mountain of paperwork that construction projects generate. Drawings. Specifications. Submittals. RFIs. Test certificates. Everything is searchable and accessible. Training should introduce these tools. Not in-depth technical training. But enough to understand what’s possible. What efficiencies can be gained? What systems might benefit your organization? Because the firms that use technology well have an advantage. They track things better. Respond faster. Make fewer mistakes.

Who Should Attend This Training

This training isn’t just for lawyers. It’s for anyone involved in EPC or construction contracts.

Project managers: run projects. But the contract defines the rules they play by. Understanding contract obligations, risk allocation, and change procedures is essential for effective project management.

Contract administrators: are on the front line. They process variations. Track compliance. Manage documentation. They need deep knowledge of contract provisions and procedures.

Procurement and commercial teams: negotiate and administer contracts. They need to understand what terms protect their organization. How to negotiate effectively. How to manage contractor and subcontractor performance.

Site engineers and construction managers: deal with contract implications daily. Variations arise from site issues. Delays happen. Quality disputes occur. Understanding contract procedures helps them manage these properly.

Legal and compliance staff: need to understand construction contracts specifically. General contract knowledge isn’t enough. Construction has unique features and terminology.

Consultants and project advisors: guide clients through complex projects. They need expertise to provide sound advice.

Subcontractor managers: coordinate multiple subcontracts. They need to understand how obligations flow down. How to manage interfaces. How to handle back-to-back provisions.

Even fresh graduates: entering the construction industry benefit. Starting with solid contract knowledge accelerates their career development.

Organizations benefit too. Standardizing contract practices across teams reduces inconsistency. Having trained staff means fewer mistakes. Better risk management. Smoother project execution.

Benefits & Career Value of Contract Management Training

Let’s be direct about what training delivers.

Clarity and mutual understanding: When everyone understands their obligations the same way, disputes decrease. Ambiguity causes conflicts. Training eliminates ambiguity.

Better risk management: Understanding how risk is allocated helps you manage it proactively. You can identify which risks you control. Which you’ve transferred. Which needs insurance or contingency.

This reduces nasty surprises. It prevents financial disasters.

Cost control: Variations and changes cost money. Managing them properly means you only pay for legitimate changes. You can track cumulative impact. You can push back on unjustified claims.

I’ve seen trained commercial teams save millions by properly managing the variation process.

Improved profitability for contractors: Understanding your contractual entitlements means claiming for events that justify compensation. Poor contract knowledge means leaving money on the table.

One contractor told me their staff used to just accept delays and absorb costs. After training, they started properly documenting and claiming. Their margins improved significantly.

Streamlined administration: Good systems and processes make contract administration efficient. Less time chasing information. Fewer mistakes. Better documentation.

Career advancement: Contract management skills are valuable. Organizations need people who can handle complex contracts. Negotiate effectively. Manage disputes.

For engineers and project managers, adding contract expertise makes you more promotable. You become the person management trusts with difficult projects.

Professional confidence: There’s a security in knowing you understand your contract. In knowing the procedures. In having the skills to handle problems.

This confidence shows in negotiations. In client meetings. In how you manage your projects.

Reduced legal exposure: Proper contract management prevents disputes. But when disputes happen, good documentation and procedure protect you.

Courts and arbitrators don’t like parties who ignore contract procedures. Who failed to give the required notices? Who didn’t document properly?

Training teaches you to build your case as you go.

How to Choose a Good Contract Management Training Course

Not all training is equal. Here’s what to look for:

Comprehensive coverage: The course should span the full lifecycle. From drafting through administration to dispute resolution. Not just contract law. Practical management skills.

EPC-specific content: General contract training won’t cut it. You need training focused on EPC and construction. Covering FIDIC contracts. Turnkey delivery. Construction-specific issues.

Balance of theory and practice: You need to understand principles. But you also need hands-on exercises. Case studies. Real-world examples.

Theory without practice leaves you unprepared. Practice without theory means you can’t adapt to new situations.

Experienced instructors: The best trainers have done this work. They’ve managed real contracts. Handled actual disputes. They bring war stories and practical wisdom.

Academic experts are fine. But someone who’s negotiated billion-dollar contracts brings different value.

Quality case studies: Real examples from actual projects teach more than hypotheticals. Look for courses using detailed, realistic case studies.

Exposure to tools and technology: Understanding CLM software and digital tools is increasingly important. The course should introduce modern approaches.

Recognition or certification: While not essential, certification from respected bodies adds credibility. It signals to employers that you’ve completed rigorous training.

Up-to-date content: Contract practices evolve. Standard forms get updated. FIDIC released new versions in 2017. Your training should reflect current practice.

Flexible delivery: For working professionals, online or modular formats help. You can’t always take a week off for training.

Good reviews and reputation: Talk to past participants. Check reviews. Ask colleagues for recommendations.

Quality training is an investment. Choose wisely.

Common Mistakes & Pitfalls in EPC Contract Management

Let me share what goes wrong. Repeatedly.

Poorly defined scope: The single biggest source of disputes. When the scope is vague, the contractor interprets it narrowly. The client interprets it broadly. Fight ensues.

Training teaches you to define the scope precisely. To use clear deliverables. To address gray areas explicitly.

Inadequate risk allocation: Sometimes contracts push all risk to one party. That party prices it high or takes shortcuts. Or goes bankrupt.

Fair risk allocation makes projects work better.

Weak variation management: Work proceeds without proper authorization. Costs mount. Then everyone argues about whether changes were ordered. Whether they’re compensable. How much do they cost?

Training emphasizes following the process. Every time. Even when it seems bureaucratic.

Subcontract mismanagement: Unclear subcontract obligations. Poor coordination. No enforcement of quality or schedule. Then the main contractor scrambles when subs fail.

Training covers subcontract best practices. Prevention beats firefighting.

Delay claims mishandled: The contractor fails to give timely notice. Or doesn’t document delays properly. Or can’t prove causation. They lose their entitlement.

Conversely, the client rejects valid claims without proper analysis. This leads to disputes that could have been avoided.

Training teaches proper claims procedure. For both sides.

Poor documentation: No site records. No meeting minutes. No correspondence files. When disputes arise, there’s no evidence.

Training hammers home the importance of documentation. Contemporary documentation beats memories years later.

Missed deadlines and notices: Contracts have strict timelines. Notice of claim within 28 days. Response within 14 days. Escalation within certain periods.

Miss a deadline? You might waive your right to claim.

Lack of dispute resolution readiness: Parties ignore early warning signs. Small issues fester. By the time they explode, positions are entrenched. Resolution is expensive.

Training emphasizes early intervention. Dispute boards. Collaborative resolution. Escalation only as last resort.

Typical Structure of an EPC Contract Management Training Course

Here’s what a comprehensive course might look like:

Module 1: Introduction to EPC Projects & Contract Types

Overview of EPC delivery. How it differs from traditional construction. When clients choose EPC. The advantages and challenges.

Introduction to FIDIC forms. Red Book basics. Yellow Book for design-build. Silver Book for EPC turnkey. When to use each. How they differ in risk allocation.

Module 2: Contract Drafting & Negotiation Skills

How to draft a clear scope. Payment structures. Milestone definitions. Performance guarantees. Liquidated damages. Risk clauses.

Negotiation strategies and tactics. Identifying interests versus positions. Finding win-win solutions. When to walk away.

Module 3: Contract Lifecycle Management Fundamentals

The stages from creation to close-out. Key activities at each stage. Roles and responsibilities. Documentation requirements.

Introduction to CLM concepts and tools.

Module 4: Risk Allocation & Contract Risk Management

Identifying project risks. Assessing likelihood and impact. Deciding who should bear each risk. Mechanisms for managing risk. Insurance. Bonds. Guarantees. Liquidated damages.

Module 5: Change Management & Variation Handling

The variation process. How to request changes. How to assess cost and time impact. Approval workflows. Documentation requirements.

Common disputes about variations and how to avoid them.

Module 6: Subcontract & Vendor Management

Drafting subcontracts. Flow-down provisions. Back-to-back terms. Interface management. Quality and compliance requirements.

Managing subcontractor performance and claims.

Module 7: Delay Analysis & EOT Claims Management

Types of delays. Critical path analysis. Concurrent delays. Notice requirements for extension of time claims.

Preparing and defending delay claims. Documentation needed.

Module 8: Contract Administration & Compliance

Day-to-day administration. Progress monitoring. Payment processes. Compliance checking. Quality assurance. Testing and commissioning.

Building and maintaining documentation systems.

Module 9: Dispute Resolution, Claims & Close-out

Understanding dispute resolution clauses. Dispute boards. Mediation. Arbitration. When to use each.

Claims preparation and defense. Evidence gathering and presentation.

Contract close-out procedures. Final account. Defect liability. Performance testing. Final release.

Module 10: Practical Case Studies & Exercises

Real-world contract reviews. Spotting issues in draft contracts. Mock negotiations. Variation order processing exercises. Claims preparation workshop.

Module 11: Tools & Digital Support for Contract Management

Overview of CLM software. Document management systems. Collaboration platforms. How technology enhances contract management.

Each module would include lectures, discussions, exercises, and case studies. The balance shifts toward practice in later modules.

Total course length might be 5-10 days, depending on depth. It could be delivered as an intensive week-long program. Or spread over weeks or months for working professionals.

Conclusion

Here’s the truth about EPC and construction contracts. They’re complex. They’re high-stakes. And they’re absolutely critical to project success.

You can have the best engineers in the world. The most skilled construction crews. State-of-the-art equipment. But if your contract management is weak, the project can still fail. Disputes will eat profits. Delays will pile up. Relationships will sour. Legal battles will drag on for years.

Training doesn’t just prevent disasters. It improves everything. Projects run smoothly. Risks are managed better. Changes are handled efficiently. Disputes are resolved quickly. For individuals, contract management skills are career accelerators. Organizations need this expertise desperately. Having it makes you valuable.

For organizations, trained staff means fewer mistakes. Better risk management. Improved profitability. Stronger client relationships. The investment in training pays back many times over. If you’re considering training, use the checklist earlier. Find a course that covers the full spectrum. That’s practical and hands-on. That’s taught by experienced practitioners. That reflects current industry practice. Don’t settle for generic contract training. EPC and construction are specialized. Your training should be too. The stakes are too high to wing it. Get trained. Get good. Get ahead.

Frequently Asked Questions

What types of projects need EPC contract management training?

Large-scale infrastructure projects like power plants, refineries, highways, metro systems, and industrial facilities typically use EPC contracts. However, any project involving design, procurement, and construction under a single contract benefits from this training. Even smaller design-build projects share similar contract management challenges and risk allocation issues that make training valuable.

Is training useful for small-scale construction projects or only for large EPC projects?

While training focuses on large EPC projects, the principles apply broadly. Small projects face similar issues with scope definition, variations, risk allocation, and subcontractor management. The scale differs, but the contract management fundamentals remain the same. Understanding these principles helps professionals at any project size avoid costly mistakes and disputes.

Will training help in managing subcontractors effectively?

Absolutely. Training covers subcontract drafting, flow-down provisions, interface management, and performance monitoring. You’ll learn how to align subcontract terms with main contract obligations. How to coordinate between multiple subs. How to enforce quality and schedule requirements. And how to handle subcontractor delays and claims while protecting your position with the client.

Can certified training reduce the chances of disputes or legal issues?

Yes, significantly. Training teaches you to draft clear contracts, document properly, follow correct procedures, and handle changes systematically. You learn to spot potential disputes early and resolve them before they escalate. Proper notice, timely documentation, and understanding your contract rights all reduce disputes. When disputes do occur, you’re better prepared to defend your position.

How much experience is ideal before enrolling in this training?

Training benefits everyone from fresh graduates to seasoned professionals. Beginners gain foundational knowledge that accelerates their career development. Experienced professionals fill knowledge gaps, learn systematic approaches, and update their understanding of current practices. Even veterans discover new perspectives through case studies and peer discussions. No prior contract experience is required for most courses.

Is knowledge of standard contract forms like FIDIC necessary before training?

Not at all. Good training courses start with FIDIC basics and build from there. You’ll learn what FIDIC is, why it matters, and how different FIDIC books allocate risk. The course introduces these concepts systematically. However, if you’ve worked with FIDIC contracts before, you’ll find the training helps you understand provisions you previously found confusing.

Does the course cover delay claims, EOT, change orders, and variation orders?

Yes, comprehensive courses dedicate significant time to these topics. You’ll learn variation procedures, cost and time impact assessment, approval workflows, and documentation requirements. Delay analysis methods, extension of time claims preparation, notice requirements, and concurrent delay handling are typically covered in detail. These are among the most dispute-prone areas, so training emphasizes them heavily.

Are there digital tools covered for contract lifecycle management?

Most modern courses introduce CLM software, document management systems, and digital collaboration platforms. While not in-depth technical training, you’ll understand what these tools do, how they improve efficiency, and what features to look for. Some courses include hands-on demonstrations. Understanding available technology helps you implement better systems in your organization.

Is training more theoretical or does it include practical, real-world case studies?

Quality training balances both. You need theory to understand principles and adapt to different situations. But practical case studies, exercises, mock negotiations, and real contract reviews teach application. Look for courses offering at least 40% hands-on content. The best courses use actual project examples with lessons learned from real disputes and successful contract management.

How does such training benefit a construction firm, not just individuals?

Organizations with trained staff make fewer costly mistakes. They manage risks better, document properly, and handle disputes effectively. Standardized contract practices across teams reduce inconsistency. Trained commercial teams negotiate better terms and identify cost savings. Better subcontractor management improves quality and schedule. Overall, firms see improved project profitability, reduced legal exposure, and stronger client relationships.